AI and automation are transforming global manufacturing, driving historic gains in efficiency, quality, and adaptability. Powered by machine learning, IoT sensors, and smart robotics, these innovations are enabling factories to achieve unprecedented productivity while staying agile in a changing world.

The Power of AI in Manufacturing

AI brings intelligence to every stage of production. From design through delivery, advanced algorithms learn from vast data streams, help teams solve complex problems, and automate repetitive tasks. Whether it’s optimizing intricate workflows or predicting equipment failures, AI gives manufacturers the ability to outpace competition and meet ever-changing customer demands.

Key Applications of AI in Manufacturing

Predictive Maintenance

AI uses real-time sensor data to monitor machine health, predict equipment failures, and schedule maintenance only when necessary. This “just-in-time” approach:

Quality Control

Computer vision and machine learning enable automated defect detection far more reliably than the human eye. These systems:

Supply Chain Optimization

AI-powered analytics help manufacturers seamlessly manage inventory, forecast demand, and optimize production schedules. In practice, this results in:

Benefits of Automation in Production Lines

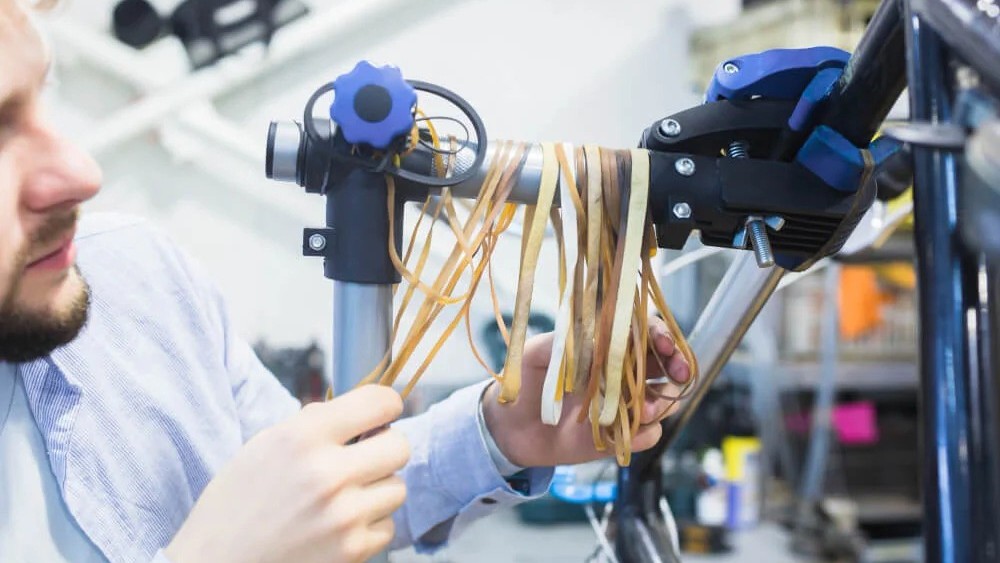

Future Trends in AI and Robotics

Conclusion: Embracing the Smart Factory Revolution AI and automation are no longer futuristic dreams—they are the present and future of manufacturing excellence. Those who embrace these technologies will deliver higher-quality products, faster and safer, while maintaining the agility to succeed in a fast-changing world. Smart factories aren’t just coming—they’re here, driving the next wave of industrial success.

Welcome to the world of end-to-end digital manufacturing where cutting-edge technology and innovation collide to deliver exceptional products at lightning-fast speeds.

© 2025 ZeQube Technologies, All rights reserved