Additive Manufacturing (AM), commonly known as 3D printing, is reshaping how products are designed, developed, and produced across industries. By building objects layer by layer directly from digital blueprints, AM enables rapid prototyping, mass customization, and the creation of complex geometries impossible with traditional manufacturing. As technology advances, its unique advantages are driving a profound transformation in manufacturing workflows, cost structures, and innovation cycles.

Overview of Additive Manufacturing Technologies

Additive manufacturing encompasses several distinct technologies, each suited for different applications:

- Powder Bed Fusion (PBF): Using lasers or electron beams to selectively fuse powdered metals or plastics, this technology produces highly detailed, functional parts with mechanical properties comparable to traditional methods. Common processes include Selective Laser Sintering (SLS) and Selective Laser Melting (SLM).

- Material Extrusion: Most familiar through fused filament fabrication (FFF), it deposits melted thermoplastic filaments layer by layer. It’s popular for prototyping and low-cost production.

- Vat Polymerization: Techniques like Stereolithographic (SLA) cure liquid resins with light, yielding parts with smooth finishes and fine details, ideal for medical models and dental applications.

- Direct Energy Deposition (DED): Primarily used for metal repair and manufacturing, DED directs focused energy to melt feedstock material, allowing on-demand manufacturing or rebuilding of components.

Other emerging technologies include Binder Jetting, which uses liquid binders on powder beds for rapid, high-volume production, and innovations in multi-material printing that enable complex composite parts.

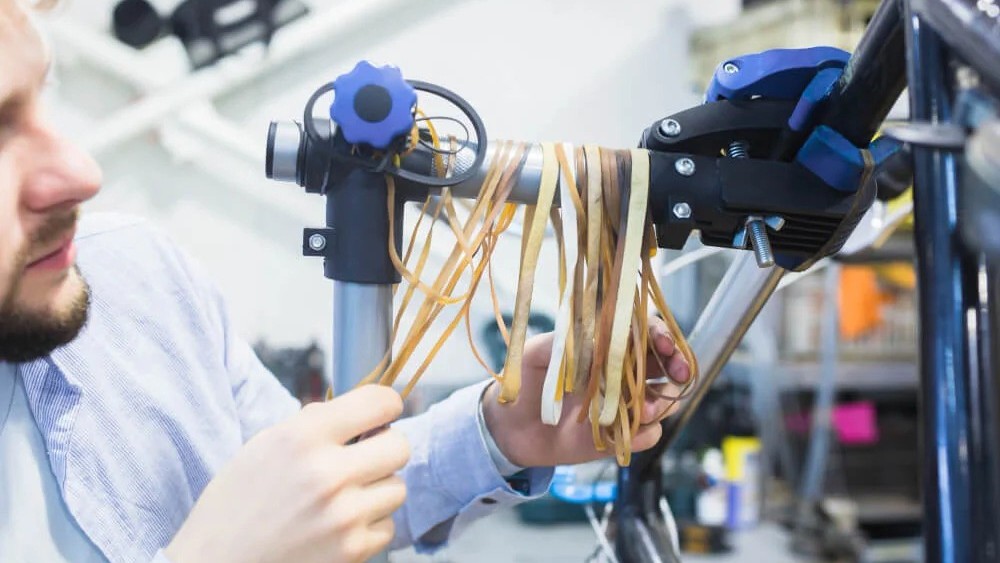

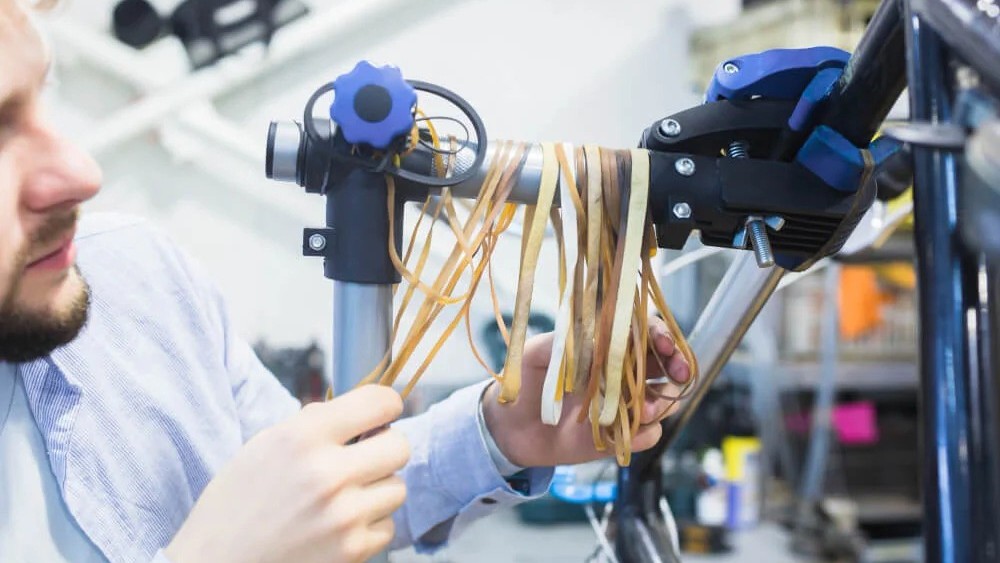

Benefits of 3D Printing in Product Development

- Rapid Prototyping: AM dramatically shortens product development cycles by enabling designers to quickly create, test, and iterate physical prototypes. This accelerates innovation and reduces costly design errors early on.

- Customization and Complexity: Unlike traditional subtractive methods, AM can produce intricate shapes, hollow structures, and lattice frameworks tailored to specific functional needs without additional tooling costs. This is particularly valuable in personalized medical devices or lightweight aerospace components.

- Reduced Lead Times and Inventory: Additive manufacturing can produce near-final parts on demand, reducing dependency on large manufacturing runs and warehousing. This supports just-in-time supply chains and localized production ecosystems.

- Material Efficiency and Sustainability: AM minimizes waste by precisely depositing material only where needed. It also enables the use of recycled powders and bio-based resins, supporting greener manufacturing practices.

Industry-Specific Applications and Case Studies

Aerospace

- Additive technologies are used for making lightweight, structurally optimized parts such as turbine blades and brackets. Companies like Boeing and Airbus adopt Powder Bed Fusion and DED for both prototyping and production, reducing weight to improve fuel efficiency and create complex internal channels for cooling.

Healthcare

- Customized implants, prosthetics, and surgical guides are rapidly produced using Vat Polymerization and metal AM technologies, offering patient-specific solutions with improved outcomes and reduced complications. The integration of AI with AM further tailors designs for biomechanical compatibility.

Automotive

- AM supports low-volume production of tailored components, spare parts, and tooling fixtures. Startups and OEMs implement Binder Jetting and Material Extrusion for rapid tooling and agile manufacturing, shortening development cycles for electric vehicles and enhancing supply chain resilience.

Consumer Electronics

- Manufacturers use AM for prototyping intricate electronic casings and integrating cooling solutions with optimized airflow channels developed through generative design algorithms. This allows faster market entry and design flexibility.

Construction and Agriculture

- Large-scale AM printers fabricate components for modular building construction using concrete and composite materials, enabling cost-effective, sustainable infrastructure development. In agriculture, 3D-printed custom tools and sensor housings support smart farming initiatives.

The Future of Additive Manufacturing: Trends and Innovations

- Automation of AM production lines brings end-to-end digital workflows and robotic post-processing, increasing throughput and reducing labor costs.

- Development of novel materials like high-performance polymers, composites, and biodegradable resins expands application fields.

- Integration with AI and IoT enables real-time quality control, predictive maintenance, and adaptive printing strategies.

- Decentralized additive manufacturing networks empower local and on-demand production, reducing logistics burdens and environmental impact.

Conclusion

Additive manufacturing is no longer a niche prototyping tool — it’s a foundational technology driving modern, flexible, and sustainable production. Companies pioneering AM across sectors benefit from accelerated innovation, reduced costs, and the ability to deliver highly customized products at scale. As materials and automation improve, the role of additive manufacturing in production will only grow, shaping the factory floors and supply chains of the future.